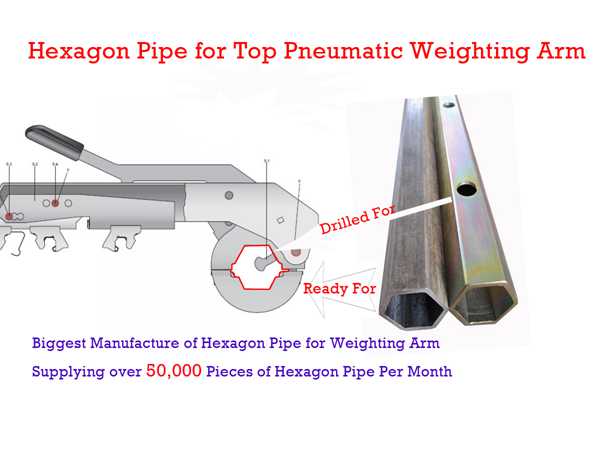

Hexagonal Steel Tubing for Weighting Arms

Outside Diameter(O.D): 38mm

Wall Thickness(W.T): 3.0mm

Functions of shaft: Hexagonal steel tubing for weighting arms in textile machines serve a specific purpose in the textile industry. Textile machines often require precise tension control and stability to ensure the quality of the textile products being produced.

Description & Specifications

TYP Steel LLC’s Hexagonal Steel Tubing for Weighting Arms is a premium solution designed to optimize the performance of textile machinery. Crafted with precision and durability in mind, this tubing is engineered to provide superior structural stability and load-bearing capabilities, essential for the precise operation of Weighting Arms in textile machines.

The hexagonal design of the tubing is a key feature, offering enhanced strength and rigidity compared to traditional shapes. This ensures that the Weighting Arms remain stable and well-supported, contributing to the overall efficiency and reliability of the textile machinery. The tubing is manufactured using high-quality steel, guaranteeing longevity and resilience in the challenging conditions of textile manufacturing.

Our Hexagonal Steel Tubing is tailored to meet the unique demands of the textile industry. It is available in various dimensions, allowing for customization to fit specific Weighting Arm specifications. This versatility ensures seamless integration into different types of textile machinery, providing manufacturers with a reliable and efficient solution.

In addition to its robust construction, the tubing undergoes stringent quality control processes at TYP Steel LLC to meet industry standards. Whether your textile machinery operates at high speeds or demands precision in every movement, our Hexagonal Steel Tubing is engineered to exceed expectations.

Upgrade your textile machinery with TYP Steel LLC’s Hexagonal Steel Tubing for Weighting Arms, where quality, durability, and innovation converge to enhance the performance and longevity of your equipment. Trust in our commitment to excellence as a leading manufacturer in the industry.

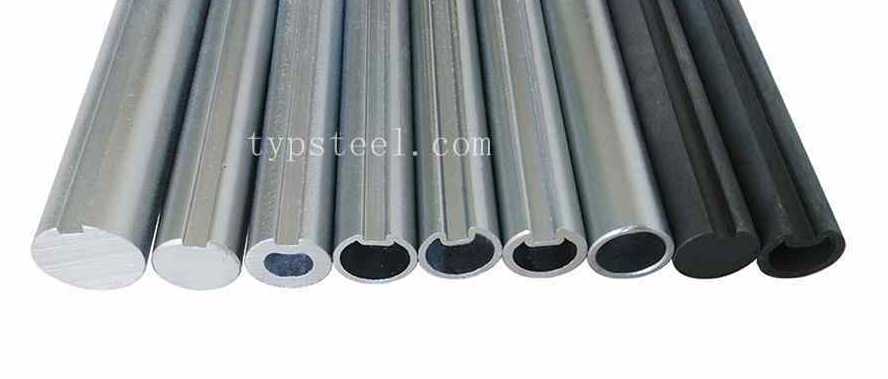

| Drive Shaft for Garage Doors & Commercial Doors | ||||

| Items | Round Shaft | Tube Shaft Hexagonal | Hollow Shaft with Keyway | Solid Shaft with Keyway |

| Outside Diameter |

ø18mm, ø20mm ø25.4mm, ø31.75mm, ø34.8mm, etc. |

35.6*31.8*3.0mm |

1"=25.40mm 1.25"=31.75mm 34.8*3mm |

1"=25.40mm 1.25"=31.75mm |

| Wall Thickness | 1.8mm, 2.0mm, 2.3mm, 3.0mm, 4.0mm, 11gauge, 12gauge, 14gauge, 16gauge, etc. | ~ | ||

| Keyway | ~ | ~ | 1/4”(=6.35mm) | |

| Lengths |

Galvanized: 0.5-7.5 meters Dacromet, Black: 0.5-11.8 meters |

|||

| Distortion | ~ | Max 1°/m | ||

| Straightness | Max 2.5mm/m | |||

| Surface Treatment | Galvanized, Dacromet, Black with anti-rust oil, Fe/Zn 10 | |||

| Material | Carbon Steel SAE 1020 / 20# / ZStE 340 /ST52 | Q235 (ASTM A36) | ||

| Packing |

Tubular shaft & hollow shaft, 30/40/50/60 pieces per bundle Solid shaft & keyed shaft, 20/30/50 pieces per bundle |

|||

| Samples | Free samples to designated address | |||

| Delivery Time | Within 25 days after order confirmed | |||

| Customization | If not listed above, we can customize drive shaft according to samples or drawings. | |||

|

||||

Hollow Shaft with Keyway in Cold Drawn Process

Hollow shaft with keyway is cold drawn from fixed mould

Solid Shaft with Keyway in Cold Drawn Process

Solid shaft with keyway is cold drawn from fixed mould

Black Solid Shaft with Keyway

Surface Treatment: Black

Galvanized Solid Shaft with Keyway

Surface Treatment: Galvanized

Packing Method and Quantity

The shafts are packed in square-shape bundles. The quantity is 20/30/40/50/60 pieces per bundle.

Shaft Loading

The shaft are delivered by container.

Dirve shaft tensile test

The testing procedure designed to assess the tensile strength of a drive shaft

Dirve shaft torsion test

The test may involve applying torque to the drive shaft and measuring its response, checking for any deformation, or assessing the material’s fatigue strength.

Dirve shaft torsion test result

The goal is to identify potential weaknesses or points of failure in the drive shaft design, which helps manufacturers produce reliable and durable components for vehicles.

FAQ about Hexagonal Tubing for Weighting Arms