ASTM A53 Steel Pipe

- Sizes Range: OD, 10-168mm; W.T, 2-12mm; Length, 2m-12m or as required

- Schedules: S/10, S/20, S/40, STD, S/60, S/80, XH, S/100, S/120, S/140, S/160 and XXH

- Steel Grades: ASTM A53, Grade A and Grade B

- Standards: ASTM A53.

- Application: Grade A is suitable for general structural applications, while Grade B is intended for use in mechanical and pressure applications.

ASTM A53 steel pipe is titled Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.

The ASTM A53 standard is a specification developed by ASTM International, formerly known as the American Society for Testing and Materials. ASTM A53 is titled “Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.” This specification outlines the requirements for seamless and welded carbon steel pipes, both black and hot-dipped galvanized, intended for ordinary uses in conveying gas, steam, water, and air.

The ASTM A53 Steel Pipe is widely used in Construction, Oil and Gas Industry, Water Supply Systems, Mechanical and Pressure Applications, HVAC Systems, Piling and Foundation Projects, Fencing and Handrails, Automotive Industry and General Engineering etc. Grade A is suitable for general structural applications, while Grade B is intended for use in mechanical and pressure applications. The choice between seamless and electric resistance welded (ERW) pipes also depends on factors such as pressure requirements and cost considerations.

| Chemical Composition & Mechanical Properties of ASTM A53/ASME SA53 Grade A/Grade B | ||||||||||||||

| Steel Grade | C | Mn | P | S | Cu | Ni | Cr | Mo | V | Tensile Strength | Yield Strength | Elongation |

Delivery Condition |

|

| max. % | MPa | % | ||||||||||||

| TYPE S | Grade A | 0.25 | 0.95 | 0.05 | 0.045 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | 330 min | 205 min | 20 | Annealed |

| Grade B | P | S | 0.05 | 0.045 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | 415 min | 240 min | 20 | Annealed | |

| Product Name | ASTM A53 steel pipe is titled Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless. |

| Standards | ASTM A53/ASME SA53 |

| Sizes(OD) | OD (Outside Diameter) Range: DN50-DN250, 2"-10" |

| Nominal Wall Thickness | SCH5S SCH10S SCH10 SCH20 SCH30 SCH40 SCH60 SCH80 SCH100 SCH120 SCH140 SCH160 Sth XS XXS |

| Straight Length Range | 3000 mm – 16000 mm |

| Straightness | 1:1000 |

| Production Method | Steel bar - pierced shell - seamless steel tube by cold drawn / hot rolled |

| Certification | Mill test certificates will be issued according to EN10204.3.1 |

| Material Standard | The tubes Shall be Seamless, and the testing shall be as per A 450 / A450M. |

| Application | Application: apply to the heat exchangers, condensers and heat transfer equipment and similar pipe. |

| Inspection | All ASTM A53 steel pipe can accept third party inspection. |

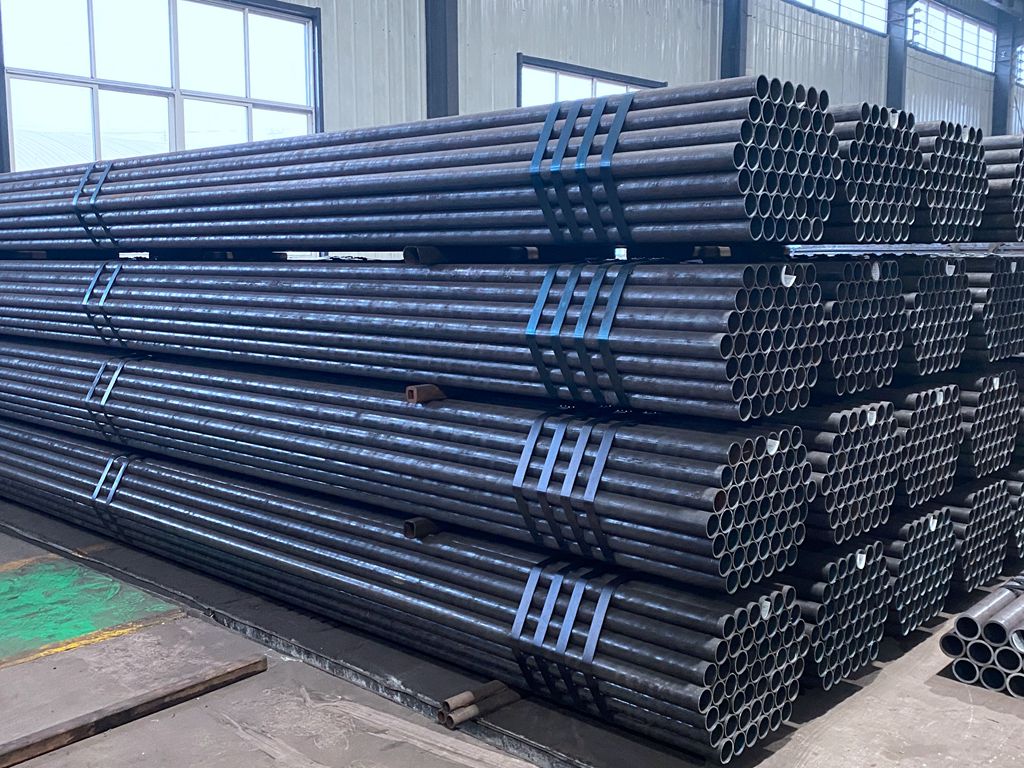

| Package | Packed in wooden box or bundles protected with plastic paper, and suitably protected for sea-worthily delivery or as requested. |

| Marking | The Product marking shall include ASTM A53 type E/S/F manufacturer's name, Diameter and timetable (from 10 to 160 and XXS), ASTM A53 designation, Heat number, Pipe Length. |

| Delivery Time | 10-30 days for production |

Products Details

Automatic Punching Production Line

Production Range: OD40-90 mm

Cold Drawn Machine

Production Range: OD40-114 mm

Hydraulic Cold Drawn Machine

Production Range: OD90-275 mm

Steel pipe surface pre-treatment

Pickling, Phosphating and Saponification

Furnace

Normalizing Tempering

Honing Machine

Honing Machine & SRB Machining

CNC Machines

Fixed length, flush, chamfered

Alloy Steel Mechanical Tubing

Alloy Steel Mechanical Tubing

ASTM-A106-Grade-B-Seamless-Pipe-Packing

ASTM-A106-Grade-B-Seamless-Pipe-Packing

ASTM A192 Seamless Carbon Steel Tubes Packing

ASTM A192 Seamless Carbon Steel Tubes Packing

cold drawn seamless tubing packing

cold drawn seamless tubing packing

ASTM A179 Seamless Steel Tube Packing

ASTM A179 Seamless Steel Tube Packing

Test and Inspection during ASTM A53 Steel Pipe Production

During the production of ASTM A53 pipes, various tests and inspections are conducted to ensure that the pipes meet the specified requirements outlined in the ASTM A53 standard. These tests and inspections are crucial for ensuring the quality, integrity, and compliance of the pipes. Here are some common tests and inspections carried out during ASTM A53 pipe production:

Automotive Steel Pipe Blasted

For automotive use

automotive steel pipe fixed length

Fixed length

automotive steel pipe long

Fixed length

Automotive-Steel-Pipe

Automotive-Steel-Pipe

automotive-steel-pipes-packing

automotive-steel-pipes-packing

automotive-steel-tubes-chamfered

automotive-steel-tubes-chamfered

Heat-Exchanger-Pipes

Heat-Exchanger-Pipes

ASTM-A192-Seamless-Carbon-Steel-Tubes

ASTM-A192-Seamless-Carbon-Steel-Tubes

ASTM A192 Seamless Carbon Steel Tubes marks

Marks