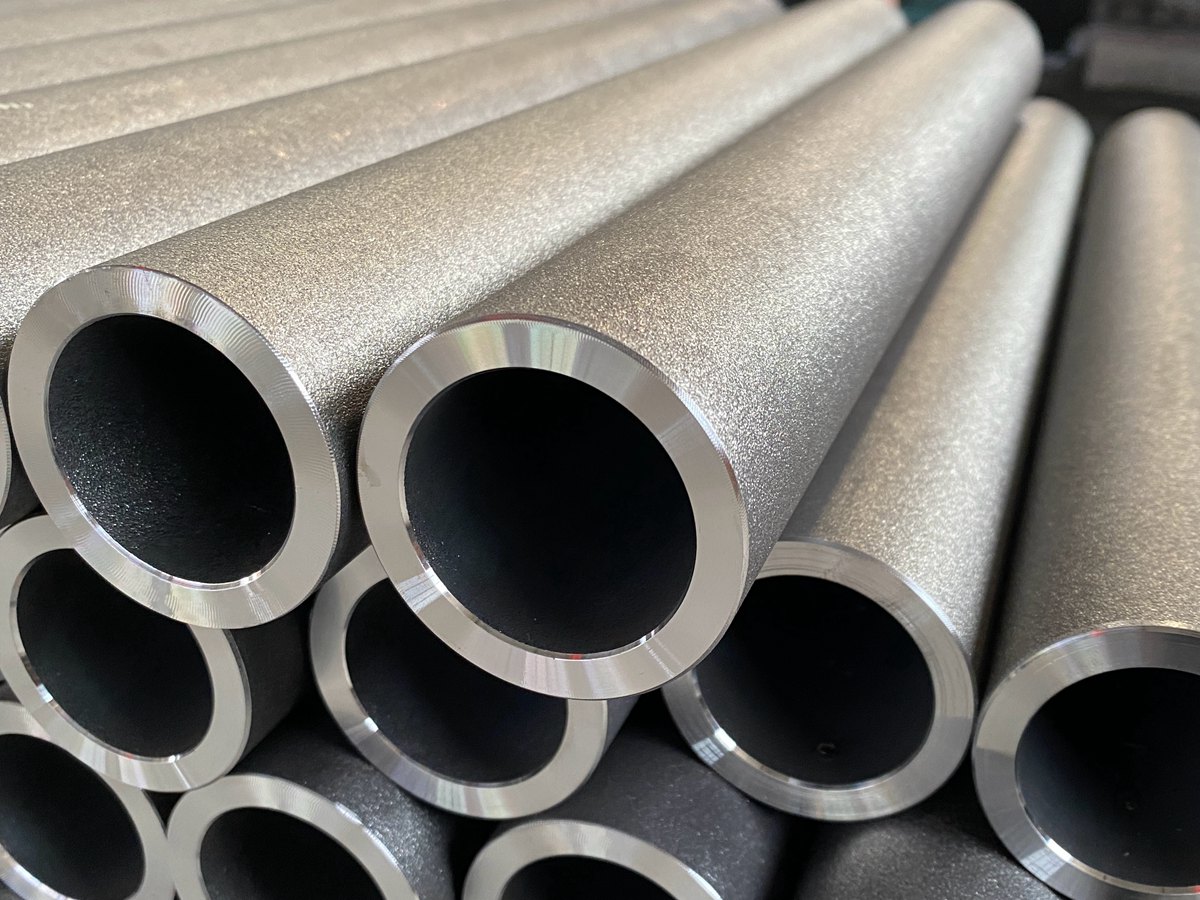

Precision Steel Tubing

Precision Steel Tubing, a hallmark of engineering precision and meticulous craftsmanship, takes center stage with TYP STEEL LLC at the helm. Crafted from the robust material that is carbon steel, this precision tubing exemplifies the dedication to excellence exhibited by TYP STEEL LLC. Renowned in the industry for their commitment to quality and precision engineering, TYP STEEL LLC delivers a product that seamlessly marries the strength of carbon steel with the exacting standards required for precision applications. From manufacturing intricacies to critical engineering solutions, Precision Steel Tubing by TYP STEEL LLC stands as a testament to innovation and reliability.

Precision Steel Tubing from TYP STEEL LLC is a testament to the seamless integration of cutting-edge manufacturing and high-quality materials. Crafted specifically from carbon steel, a material synonymous with strength and durability, this precision tubing offers a robust solution for applications where exacting tolerances and reliability are paramount. The precision engineering involved in its creation ensures consistency, reliability, and performance that meet the stringent demands of various industries.

TYP STEEL LLC employs advanced manufacturing processes to produce precision steel tubing that adheres to the highest industry standards. This tubing finds applications in a myriad of industries, from automotive engineering to complex machinery and beyond. The use of carbon steel, chosen for its strength and versatility, makes this tubing an ideal solution for projects requiring precision and structural integrity.

As a trusted manufacturer, TYP STEEL LLC places emphasis on precision, tight tolerances, and quality control in the production of their precision steel tubing. The result is a product that not only meets but exceeds industry standards, offering a reliable and customizable solution for engineering applications. The versatility of this precision tubing allows for a range of applications, contributing to advancements in various sectors.

In summary, Precision Steel Tubing from TYP STEEL LLC represents more than just a product; it embodies a commitment to excellence in material selection, manufacturing precision, and engineering innovation. Whether contributing to the precision demands of machinery or elevating the standards in automotive applications, this tubing stands as a testament to the fusion of strength, precision, and reliability.

Automotive Steel Pipe Blasted

For automotive use

automotive steel pipe fixed length

Fixed length

automotive steel pipe long

Fixed length

Automotive-Steel-Pipe

Automotive-Steel-Pipe

automotive-steel-pipes-packing

automotive-steel-pipes-packing

automotive-steel-tubes-chamfered

automotive-steel-tubes-chamfered

| Precision Steel Tubing Specifications and Description | |

| Product Name | Precision Steel Tubing |

| Standards | ASTM A513/A513M, ASTM A519/A519M, ASTM A269, DIN2391, EN 10305, etc. |

| Steel Grades | 1020, 1026, 4130, 4140, etc |

| Sizes(OD) | Rounds: 8.0mm – 168mm, Squares: 19mm-114mm, Wall Thickness: 1mm-20mm |

| Length Range | 100 mm – 16000 mm |

| Straightness | 1:1000 |

| Production Method | Steel bar - pierced shell - seamless steel tubing by cold drawn / cold rolled |

| Certification | Mill test certificates will be issued according to EN10204.3.1 |

| Material Standard | The tubes Shall be Seamless, and the testing shall be as per A 450 / A450M. |

| Application: | Automotive Components, Machinery and Equipment, Aerospace, Oil and Gas, General Engineering |

| Inspection | All Structural Steel Tubing or products can accept third party inspection. |

| Package | Packed in wooden box or bundles protected with plastic paper, and suitably protected for sea-worthily delivery or as requested. |

| Marking | The Product marking shall include the material grade, ASTM or DIN standards, size, heat no., Lot No., country of origin, certification marks, surface finish and Manufacture name or logo. |

| Delivery Time | 10-30 days for production |

Products Details

Automatic Punching Production Line

Production Range: OD40-90 mm

Cold Drawn Machine

Production Range: OD40-114 mm

Hydraulic Cold Drawn Machine

Production Range: OD90-275 mm

Steel pipe surface pre-treatment

Pickling, Phosphating and Saponification

Furnace

Normalizing Tempering

Honing Machine

Honing Machine & SRB Machining

CNC Machines

Fixed length, flush, chamfered

Alloy Steel Mechanical Tubing

Alloy Steel Mechanical Tubing

ASTM-A106-Grade-B-Seamless-Pipe-Packing

ASTM-A106-Grade-B-Seamless-Pipe-Packing

ASTM A192 Seamless Carbon Steel Tubes Packing

ASTM A192 Seamless Carbon Steel Tubes Packing

cold drawn seamless tubing packing

cold drawn seamless tubing packing

ASTM A179 Seamless Steel Tube Packing

ASTM A179 Seamless Steel Tube Packing

Key Characteristics