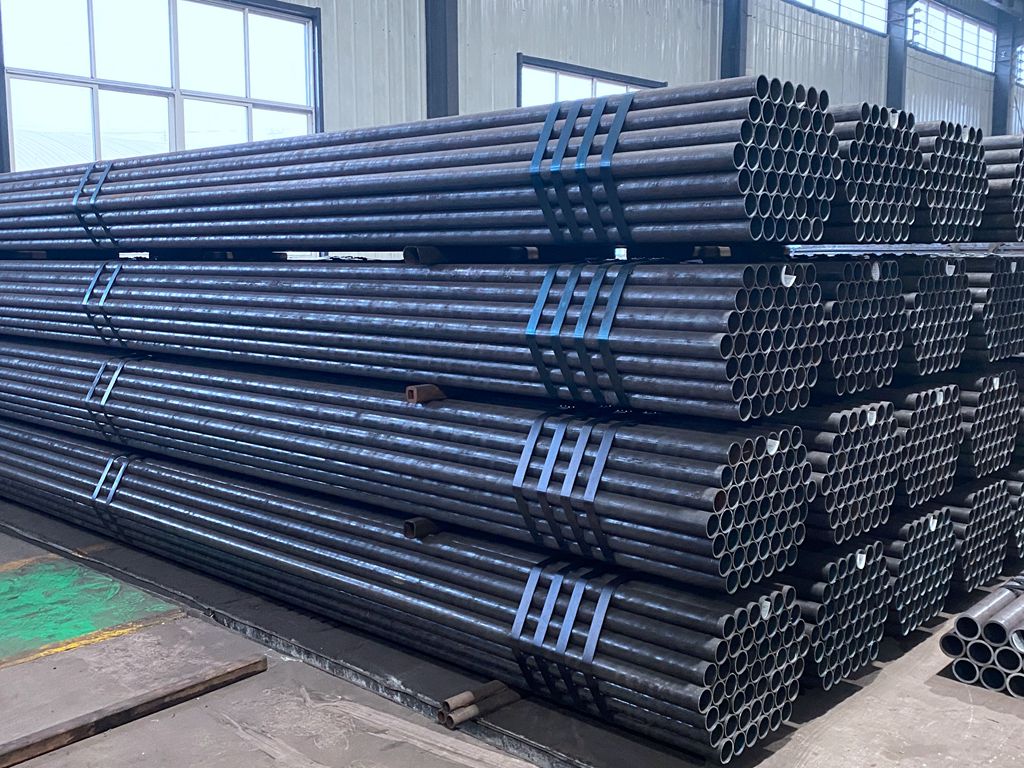

ASTM A192 Seamless Carbon Steel Tubes

- Sizes Range: OD, 10-168mm; W.T, 2-12mm; Length, 2m-12m or as required

- Schedules: S/10, S/20, S/40, STD, S/60, S/80, XH, S/100, S/120, S/140, S/160 and XXH

- Steel Grades: ASTM A53, Grade A and Grade B

- Standards: ASTM A192 / ASME SA 192

- Application: Grade A is suitable for general structural applications, while Grade B is intended for use in mechanical and pressure applications.

ASTM A53 steel pipe is titled Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.

Discover the essential details about ASTM A192 Seamless Carbon Steel Tubes, a specification designed for high-pressure applications in boilers and heat exchangers. This guide provides insights into tube sizes, steel grades, compliance with industry standards, and the advanced production methods that contribute to their reliability.

Detailed Description:

1. Sizes:

ASTM A192 Seamless Carbon Steel Tubes are available in a range of sizes suitable for various industrial applications. These tubes are commonly used in high-pressure boilers and heat exchangers, making size considerations critical for seamless integration into specific systems.

2. Steel Grades:

ASTM A192 specifies a specific steel grade for seamless carbon steel tubes intended for use in high-pressure applications. These tubes are typically manufactured from carbon steel grades such as Grade A1 or Grade C. The choice of grade depends on factors such as mechanical properties and intended service conditions.

3. Standards:

ASTM A192 establishes the standard specifications for seamless carbon steel tubes for high-pressure service. Adherence to this standard ensures uniformity in dimensions, mechanical properties, and other critical characteristics, contributing to the tubes’ reliability in demanding environments.

4. Producing Methods:

ASTM A192 Seamless Carbon Steel Tubes are manufactured using the hot-finished or cold-finished methods. The hot-finished tubes undergo final sizing and wall thickness reduction at elevated temperatures, while cold-finished tubes are produced at room temperature. Both methods are designed to meet the specified requirements for high-pressure applications.

5. Applications:

ASTM A192 tubes are specifically designed for applications in high-pressure boilers and heat exchangers. These tubes are suitable for conveying fluids at elevated temperatures and pressures, making them essential components in power generation and industrial processes.

6. Features:

The seamless nature of ASTM A192 tubes eliminates the risk of weak points and enhances their ability to withstand high pressures. The carbon steel composition provides excellent durability and resistance to corrosion, ensuring a long service life in demanding environments.

7. Quality Assurance:

Rigorous quality control measures are implemented during the production of ASTM A192 Seamless Carbon Steel Tubes. This includes testing for dimensions, mechanical properties, and non-destructive testing to ensure compliance with ASTM standards and customer specifications.

8. Compliance with Regulations:

ASTM A192 tubes are designed to meet industry regulations and standards, ensuring that they are suitable for use in critical applications where safety and reliability are paramount.

| Chemical Composition & Mechanical Properties of ASTM A53/ASME SA53 Grade A/Grade B | ||||||||||||||

| Steel Grade | C | Mn | P | S | Cu | Ni | Cr | Mo | V | Tensile Strength | Yield Strength | Elongation |

Delivery Condition |

|

| max. % | MPa | % | ||||||||||||

| TYPE S | Grade A | 0.25 | 0.95 | 0.05 | 0.045 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | 330 min | 205 min | 20 | Annealed |

| Grade B | P | S | 0.05 | 0.045 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | 415 min | 240 min | 20 | Annealed | |

| Product Name | ASTM A53 steel pipe is titled Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless. |

| Standards | ASTM A53/ASME SA53 |

| Sizes(OD) | OD (Outside Diameter) Range: DN50-DN250, 2"-10" |

| Nominal Wall Thickness | SCH5S SCH10S SCH10 SCH20 SCH30 SCH40 SCH60 SCH80 SCH100 SCH120 SCH140 SCH160 Sth XS XXS |

| Straight Length Range | 3000 mm – 16000 mm |

| Straightness | 1:1000 |

| Production Method | Steel bar - pierced shell - seamless steel tube by cold drawn / hot rolled |

| Certification | Mill test certificates will be issued according to EN10204.3.1 |

| Material Standard | The tubes Shall be Seamless, and the testing shall be as per A 450 / A450M. |

| Application | Application: apply to the heat exchangers, condensers and heat transfer equipment and similar pipe. |

| Inspection | All ASTM A53 steel pipe can accept third party inspection. |

| Package | Packed in wooden box or bundles protected with plastic paper, and suitably protected for sea-worthily delivery or as requested. |

| Marking | The Product marking shall include ASTM A53 type E/S/F manufacturer's name, Diameter and timetable (from 10 to 160 and XXS), ASTM A53 designation, Heat number, Pipe Length. |

| Delivery Time | 10-30 days for production |

Products Details

Automotive Steel Pipe Blasted

For automotive use

automotive steel pipe fixed length

Fixed length

automotive steel pipe long

Fixed length

Automotive-Steel-Pipe

Automotive-Steel-Pipe

automotive-steel-pipes-packing

automotive-steel-pipes-packing

automotive-steel-tubes-chamfered

automotive-steel-tubes-chamfered

Heat-Exchanger-Pipes

Heat-Exchanger-Pipes

ASTM-A192-Seamless-Carbon-Steel-Tubes

ASTM-A192-Seamless-Carbon-Steel-Tubes

ASTM A192 Seamless Carbon Steel Tubes marks

Marks

Test and Inspection during ASTM A192 Seamless Carbon Steel Tubes Production

During the production of ASTM A53 pipes, various tests and inspections are conducted to ensure that the pipes meet the specified requirements outlined in the ASTM A53 standard. These tests and inspections are crucial for ensuring the quality, integrity, and compliance of the pipes. Here are some common tests and inspections carried out during ASTM A53 pipe production:

Automatic Punching Production Line

Production Range: OD40-90 mm

Cold Drawn Machine

Production Range: OD40-114 mm

Hydraulic Cold Drawn Machine

Production Range: OD90-275 mm

Steel pipe surface pre-treatment

Pickling, Phosphating and Saponification

Furnace

Normalizing Tempering

Honing Machine

Honing Machine & SRB Machining

CNC Machines

Fixed length, flush, chamfered

Alloy Steel Mechanical Tubing

Alloy Steel Mechanical Tubing

ASTM-A106-Grade-B-Seamless-Pipe-Packing

ASTM-A106-Grade-B-Seamless-Pipe-Packing

ASTM A192 Seamless Carbon Steel Tubes Packing

ASTM A192 Seamless Carbon Steel Tubes Packing

cold drawn seamless tubing packing

cold drawn seamless tubing packing

ASTM A179 Seamless Steel Tube Packing

ASTM A179 Seamless Steel Tube Packing